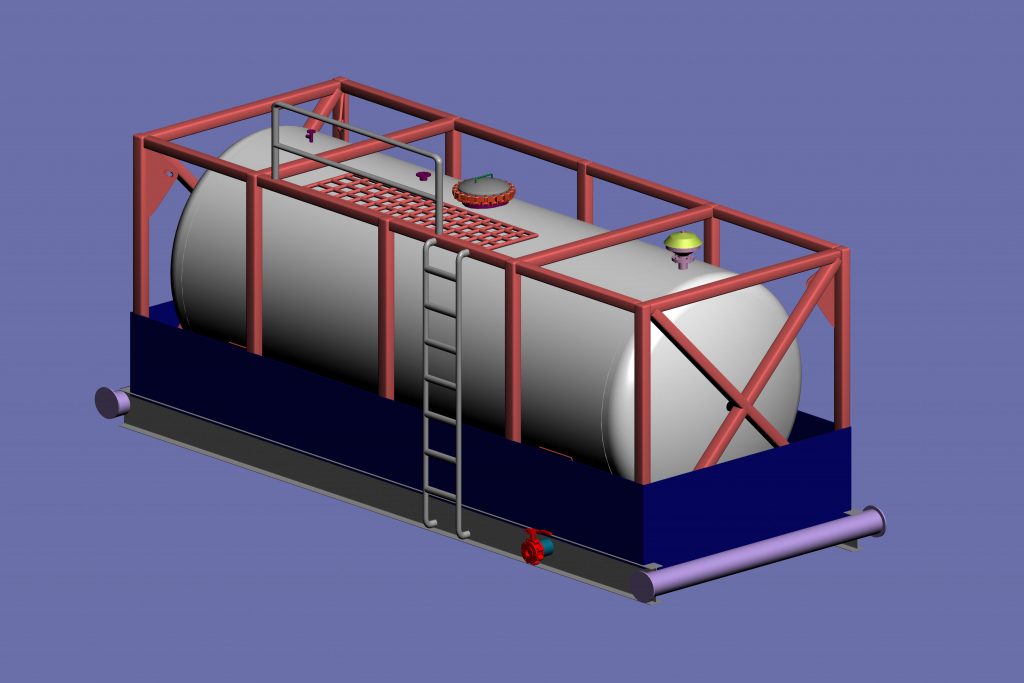

An ISO Tank is a tank container which is built to the ISO standard (International Organisation for Standardisation). ISO tanks are designed to carry liquids in bulk, both hazardous and non-hazardous. The tank is made of stainless steel and is surrounded by various types of protective layers. Al Jassar can manufacture any kind of ISO tanks for challenging mediums as per customer’s requirement